Petrochemicals

Catalytic processes with LEWA pumps

Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. The most important operations are the various splitting or cracking processes (e.g. steam cracking, hydrocracking). These processes convert long-chained hydrocarbons (e.g., naphtha) into short-chained ones.

LEWA supports your production plants with effective additive metering, as well as with the conveying and treatment of washing water and sour water.

LEWA offers you specialized solutions for the metering and conveyance of the required chemicals and products. We design pumps and systems to suit your requirements and offer you all-round support for processes such as hydrocracking.

Areas of Application in the Petrochemical Industry

LEWA pumps and metering systems are used in the petrochemical industry for many processes in the hydrocracking and steam cracking sector.

| Product applications | Chemicals | Process/System |

|---|---|---|

| Metering chemicals in the petrochemical industry | Deposit inhibitors | Distillation plant, reformer system, cracker, coker |

| Tetrachloroethylene | Reformer system, cracker | |

| Defoamers | Distillation plant, reformer system, cracker, coker | |

| Emulsion breakers | Desalination plant, distillation plant | |

| Corrosion inhibitors | Distillation plant, reformer system, cracker | |

| Metal deactivators | Cracker | |

| Sulfiding agents | Reformer system, cracker | |

| Lubricity improvers | Reformer system | |

| Oxygen scavengers, oxygen binders | Cracker |

In addition to the hydrocracking and cracking process, we also support other typical refining processes with distillation plants.

Advantages at a Glance

High-precision metering

Our metering systems are characterized by the highest precision on the market. We use proven LEWA metering pumps in various designs.

Approved materials

All materials used in our pumps and pipes are tested on their resistance to the metered fluid if possible. We happily submit all necessary certifications.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

International standards

LEWA is ISO 9001 certified. Pumps, systems and units are compliant with all major international standards such as, API, ASME, TÜV and many more.

Flexible design

You can rely on over 60 years of experience in the design of pumps, systems and units: During the project phase, we respond flexibly to design changes or adjustments required.

Tests according to your specifications

Before starting up the system, we conduct well-documented test runs according to relevant international standards or to your specifications.

Maintenance and service

No matter if maintenance, spare parts or repair - our service technicians are well trained and available worldwide. Thus, we guarantee fast response and smooth operations.

High reliability

No matter if offshore in rough seas or onshore in the hot Arabian desert: Our systems are characterized by exceptional reliability and availability even under extreme conditions.

Applications

Wet oxidation of waste water

For wet oxidation and other processes, we recommend our tried-and-tested LEWA diaphragm pumps. Ask our experts for more information!

More DetailsPolymerization

LEWA manufactures metering pumps and metering systems for polymerization which optimally meet the necessary requirements. We are happy to help.

More DetailsChemical metering in high-pressure cleaning systems

LEWA metering and process diaphragm pumps meet the specific demands for the production of melamine (trimerization of urea). Consult us!

More DetailsMetering of silane

LEWA systems meter any silane type reliably, precisely as well as in constant consistency and purity, regardless of chemical or physical attributes or process requirements.

More DetailsPolymerization in EVA reactors with process pumps

Production of ethylene vinyl acetate (EVA) with LEWA process pumps. We provide you with the right pump and advice for your application.

More DetailsProducts

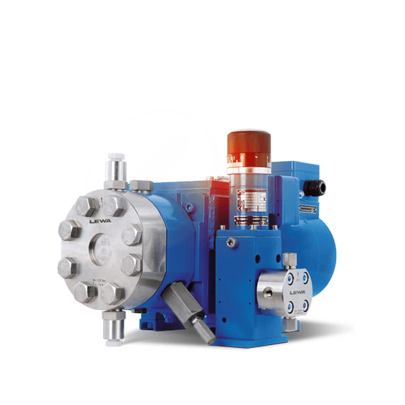

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow®: Your Solution for Advanced Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

More DetailsLEWA ecosmart®: Precision-Engineered Diaphragm Metering Pumps for Efficient Fluid Control

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

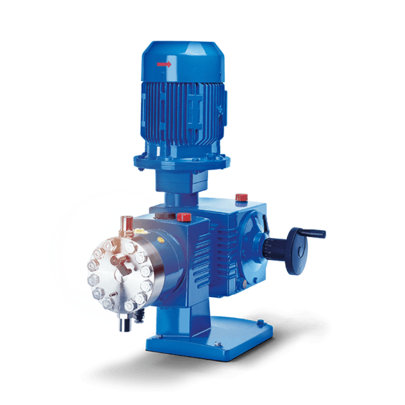

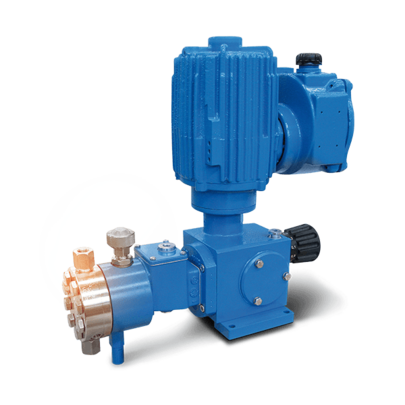

More DetailsLEWA ecodos®: Robust Mechanical Diaphragm Metering Pumps for Precision Dosing

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA MAH, MBH, MLM Series: Precision Micro-Metering Pumps for Exact Dispensing

Discover our metering pumps designed for ultra-low flow rates, offering an exceptionally cost-effective solution for proportional metering of fluid components to variable reference values. Ideal for precision applications.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps for Advanced Research Applications

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

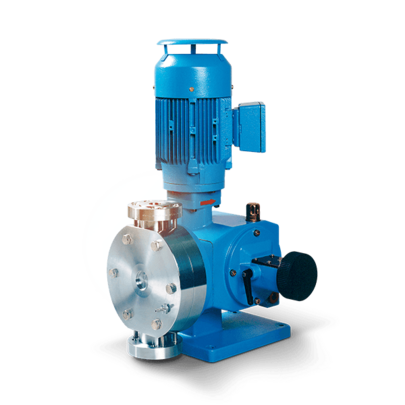

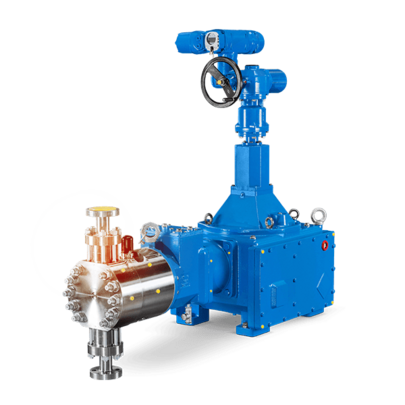

More DetailsLEWA ecoflow®: The Leading Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

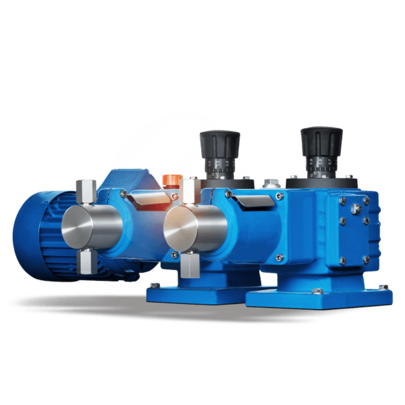

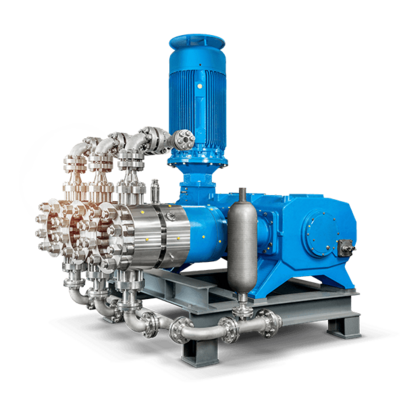

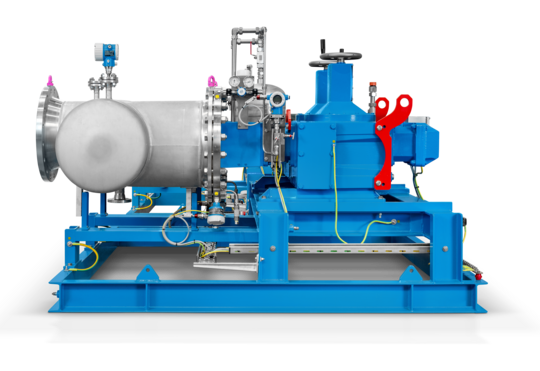

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

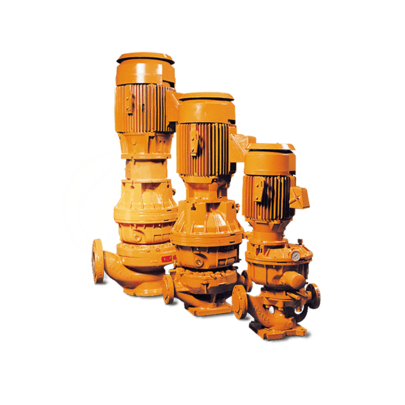

More DetailsSundyne-Marelli horizontal and vertical process pumps

With flow rates as high as 8000 m³/h and a wide variety of different pump models, Sundyne-Marelli has a pump that will fit your application.

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

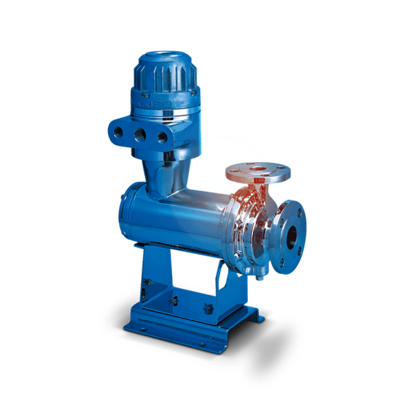

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsHMD Kontro sealless solenoid driven centrifugal pumps

HMD Kontro sealless solenoid driven centrifugal pumps are the first choice for handling toxic, aggressive, flammable, hazardous and high-value fluids. Protecting pumping fluid, people and the environment is particularly emphasized here.

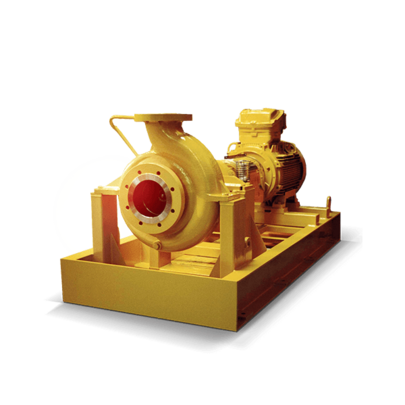

More DetailsSundyne & Sunflo high-speed centrifugal pumps & compressors

Sundyne process pumps in accordance with ISO-13709, API-610 (OH5 OH6) and Sunflo pumps are the best choice for applications with high heads and small flow rates. The centrifugal pumps feature a simple design and consistent performance data.

More DetailsSundyne Ansimag sealless magnetically driven centrifugal pump

The sealless magnetically driven centrifugal pump Ansimag is simple in construction, but effective in use. All wetted parts are lined with ETFE. With the Ansimag pumps, it is possible to meter different types of fluids, even aggressive acids and solutions at temperatures up to 121 ° C. The Ansimag series meets the ASME / ANSI B73.3 standards for sealless magnetically driven centrifugal pumps.

More DetailsWilden standard air-operated diaphragm pump

As the inventor of the compressed air-operated double-diaphragm pump, Wilden Pump & Engineering Co. introduced the first pump of this design in 1955.

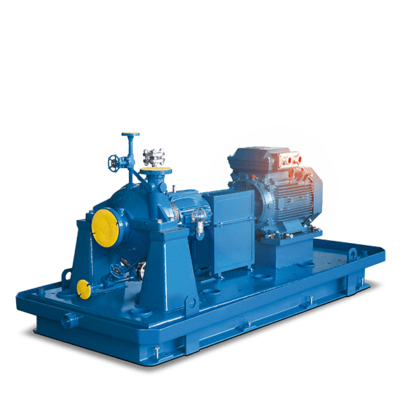

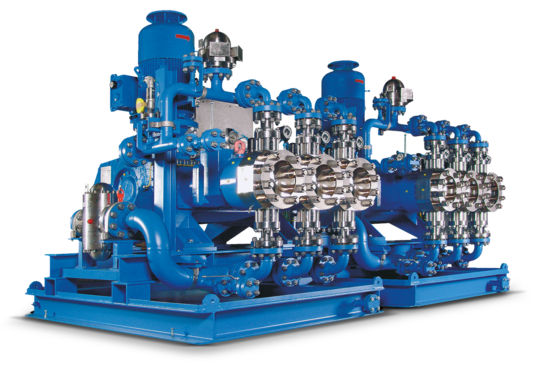

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA Bellows Pulsators

The perfect solution for generating oscillating fluid flows in vertical vessels for a quicker chemical reaction.

More DetailsLEWA Odorizing Systems

LEWA has been building odorizing systems for gases such as natural gas, oxygen, nitrogen, and carbon dioxide for more than 40 years. LEWA odorizing systems meter the odorant in question reliably, proportionally, and economically.

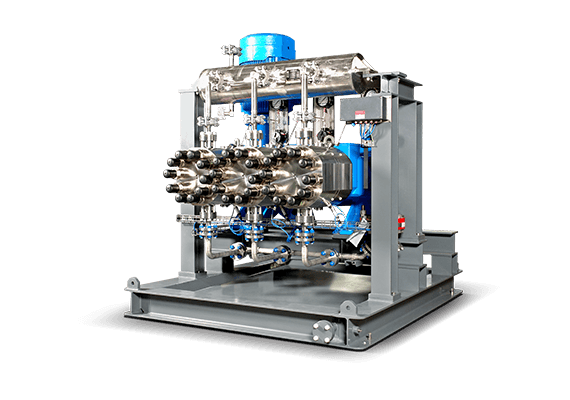

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

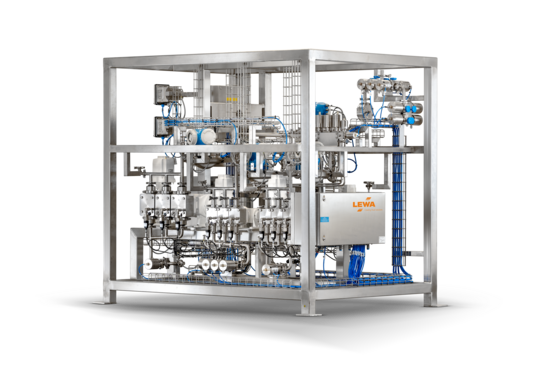

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More DetailsGeveke Nitrogen Generation Package

Complete package for continuous recovery of high purity nitrogen for oil and gas applications.

More DetailsHNPM - Micro annular gear pump series HL

Micro annular gear pumps accomplish conventional micro fluidic tasks effectively and efficiently and open up new technological fields.

.

More Details