Solutions

Essential components of LEWA metering systems:

- Precisely controllable LEWA ecoflow metering pumps

- Flowmeter with continuous signal

- LEWA microprocessor developed especially for fluid metering, connected with the control signal of the extruder control system

This permits very reliable operation using a continuously alternating monitoring of metering pumps and flowmeters. Here the measured values are not only compared, but also tested for plausibility.

The advantages of LEWA ecofoam metering systems

- Compact, tested, ready to use units for all commercially available extruders

- For all conventional blowing agents, such as CO2, propane, butane, fluorinated hydrocarbons

- Hermetically tight systems

- Integration in the process control of the complete system

- Components matched to each other from a single source

- Low maintenance costs and long service life

Background

Process description

During the production of PPE foam (or polyethylene, polystyrene, PET) the plastic melt in the extruder has a blowing agent (e.g., pentane, CO2) added under pressures up to 350 bar. The plastic expands 20 to 50 times in volume when extruded from a hole nozzle.

An important process is the production of foamed film or foamed panels. The continuous extrusion process is usually performed with so-called cascade extruders.

While the plastic granules are melted in the first extruder, after the addition of the blowing agent in the second extruder a uniform mixing of precisely this blowing agent is done. This brings the melt to a defined temperature level.

Through the low ambient pressure relative to the vapor pressure of the blowing agent, the melt expands and is calibrated in a special device to the desired panel thickness.

Source: Wikipedia, February 2012

Industries

Pumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsProducts

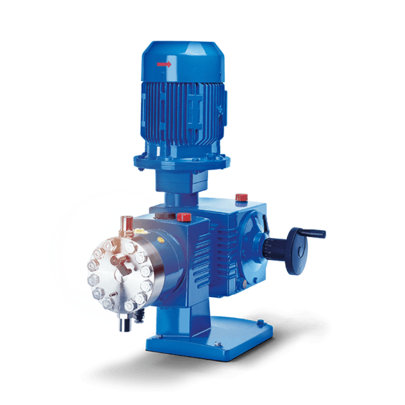

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

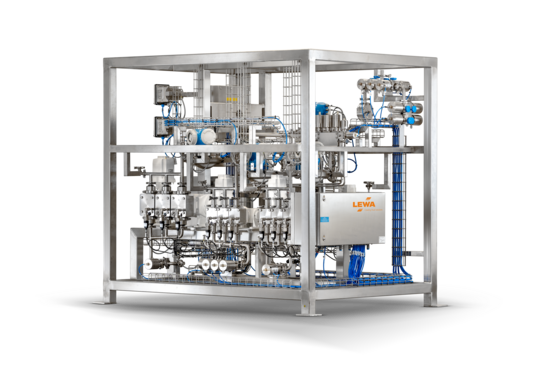

More DetailsLEWA ecofoam® Blowing Agent Metering System

Redundantly designed, absolutely leak-proof system working in combination with extruders for metering various blowing agents in plastic production.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details